Design Of Bag Filter

Design of bag filter. Low Pressure High Volume Cleaning. Think back to high school math and the circumference of a circle. In the first group a prototype is designed and then all filters can be generated from it.

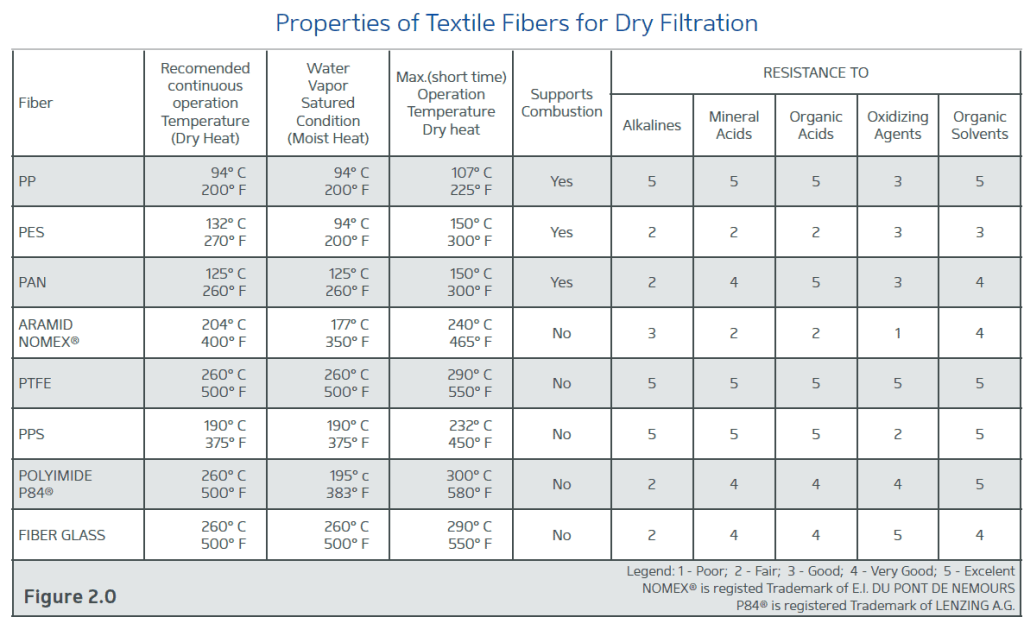

These tops typically are polypropylene or polyester with molded lifting handles. A wise filter selection can minimize process. Changes to any of these key sys- tem parameters will result in systemwide perform- ance issues.

Many methods have been proposed to design uniform filter bank 9-15. Woven fabric handles are also sewn. However tube sheets can be easily configured for your own bag size for parts commonality.

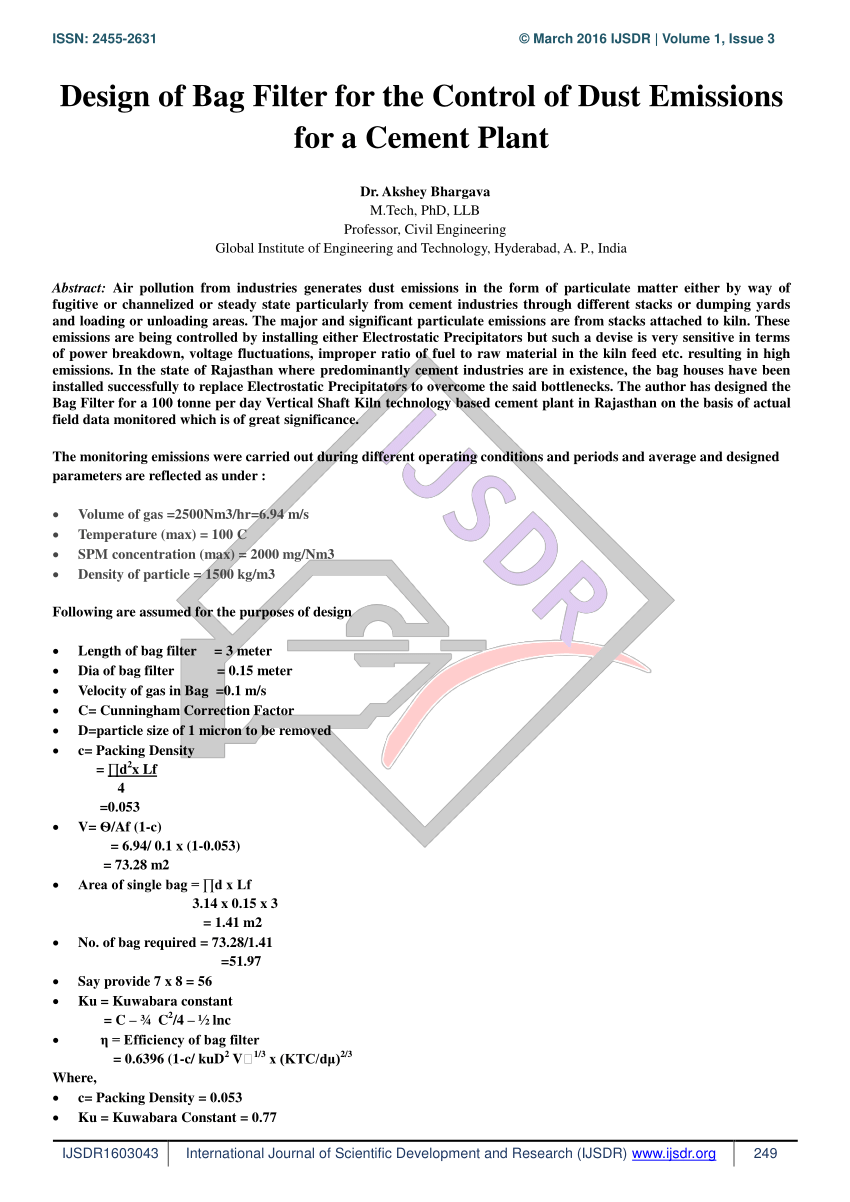

Push Palm button to read tank pressure. Pt pf pc 3-3 pt k1vf k2 ci vf 2 t3-4 Use equations 3-3 and 3-4 only as an estimate of pressure drop across shaker and reverse-air cleaning baghouses. The majority of dust collector filters are 5 inches up to 6 inches diameter round tubular cloth bags that are open at one end.

The pressure drop also decreases. Forcefully pushes air through bags. An interesting approach in this group is the one proposed by Nguyen 9 in where a prototype filter is designed using constrained.

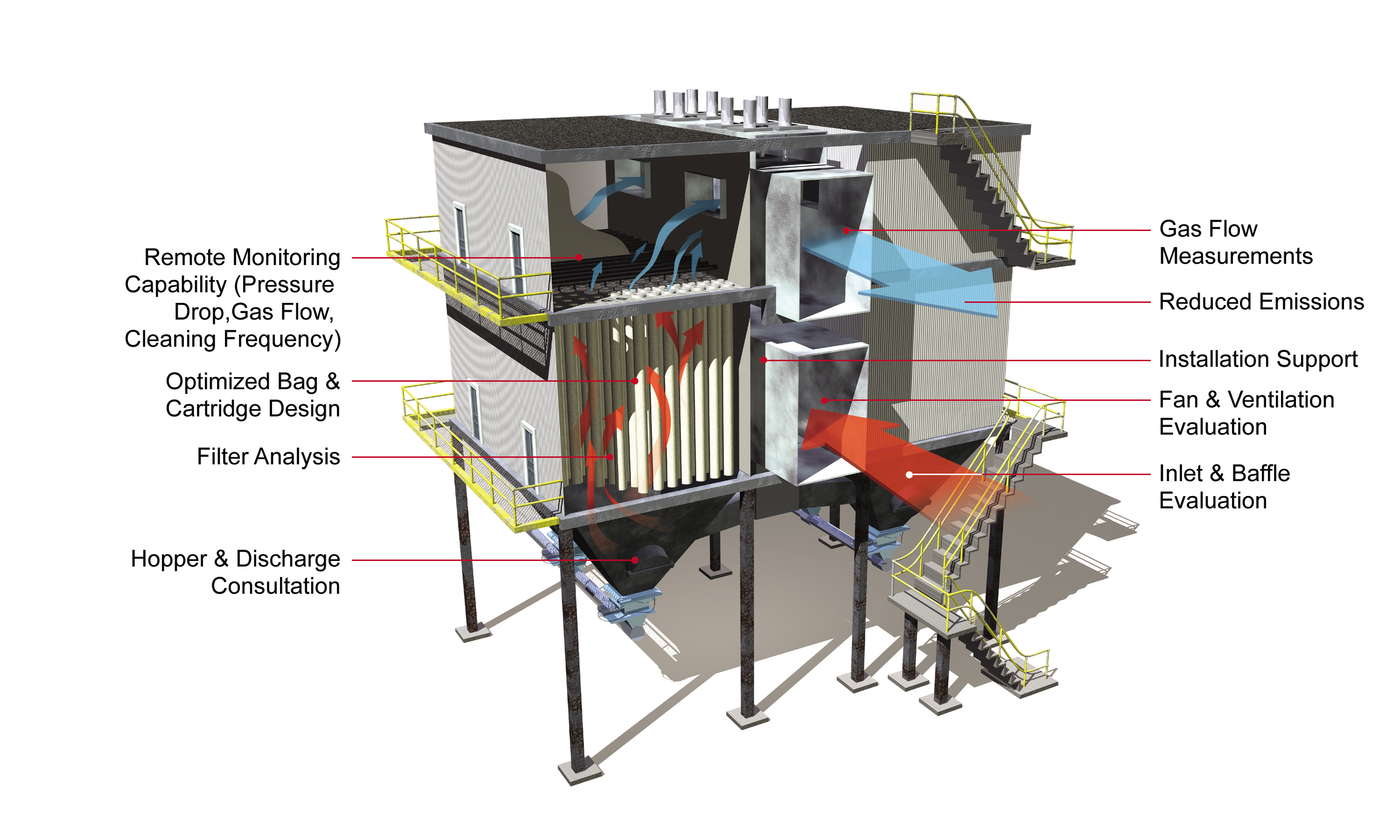

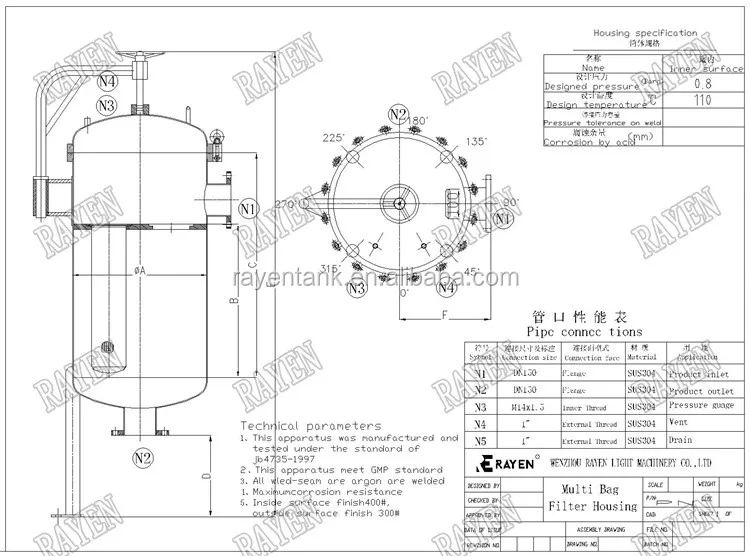

Reads air tank pressure. BAG FILTER SYSTEM SIZING IMPORTANT FACTOR TO CONSIDER WHEN SIZING FILTER BAG HOUSING APPLICATIONS The system should be designed using a filter bag with as large a surface area as possible. Filter media from 44 ft 2 to 21818 ft 2 is available in this design series.

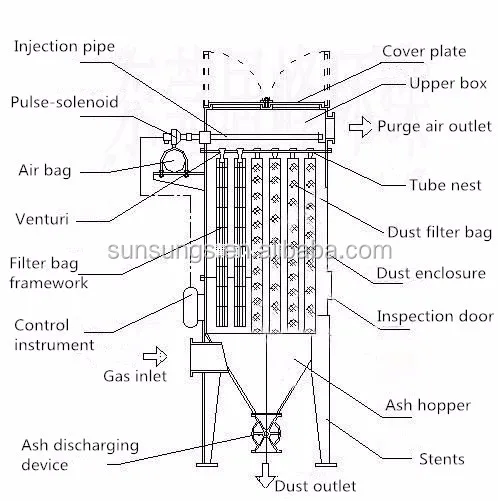

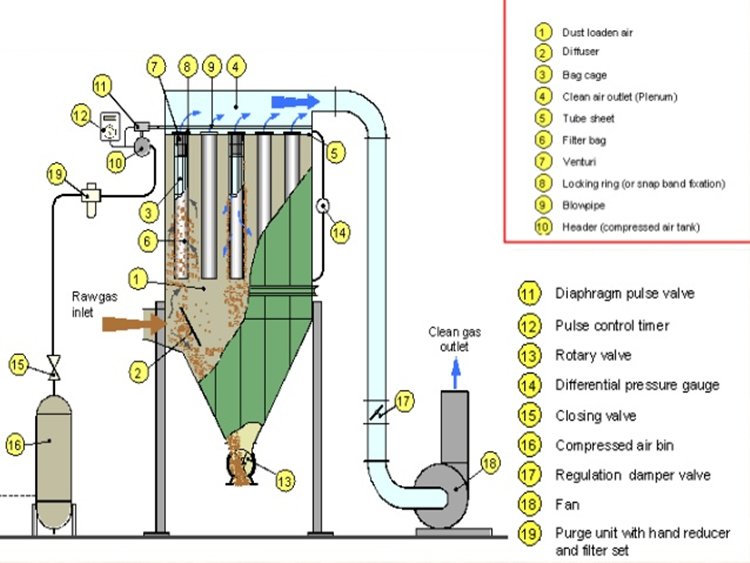

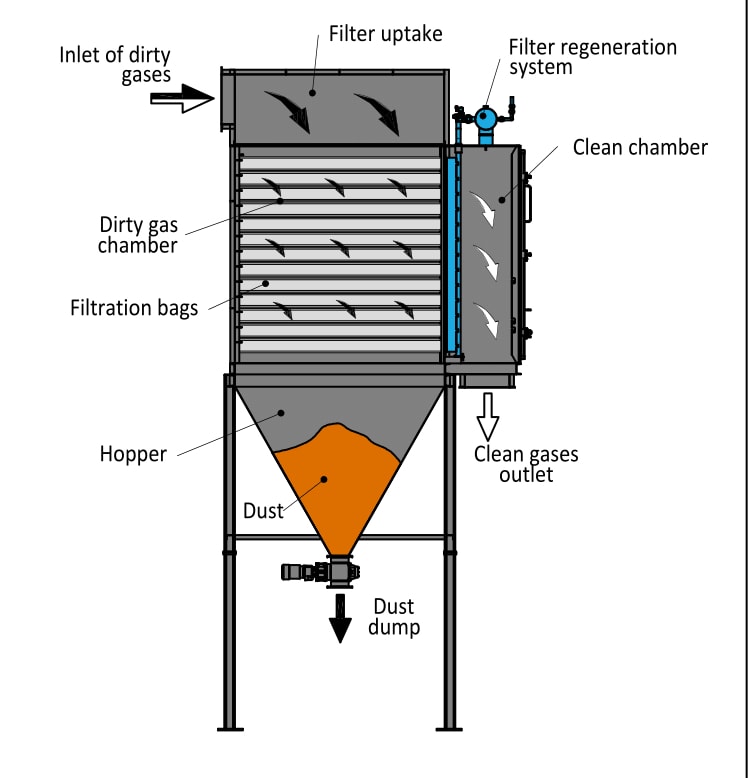

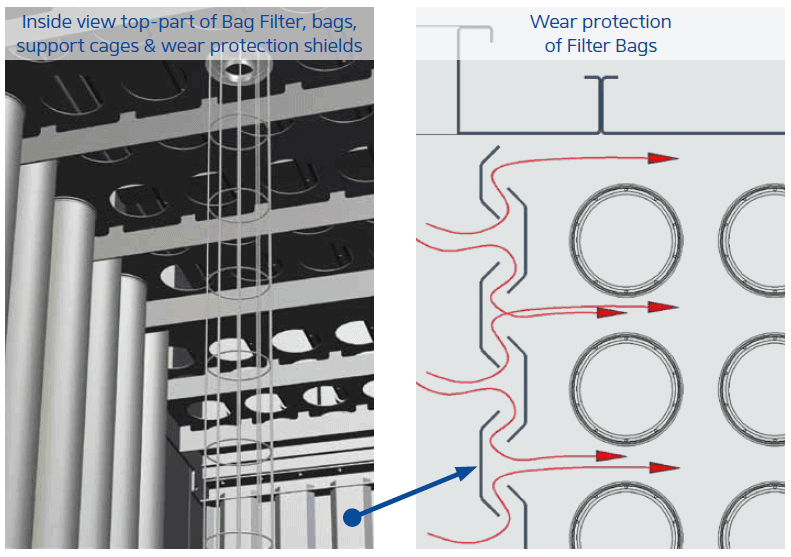

Working of Bag Type Fabric Filters In pneumatic conveying systems handling fine or dusty material the method of filtration that has become almost universally adopted is a bag type fabric filter. Bility is called bag reach and is the maximum number of rows from the nearest walkway.

The pressure drop also decreases.

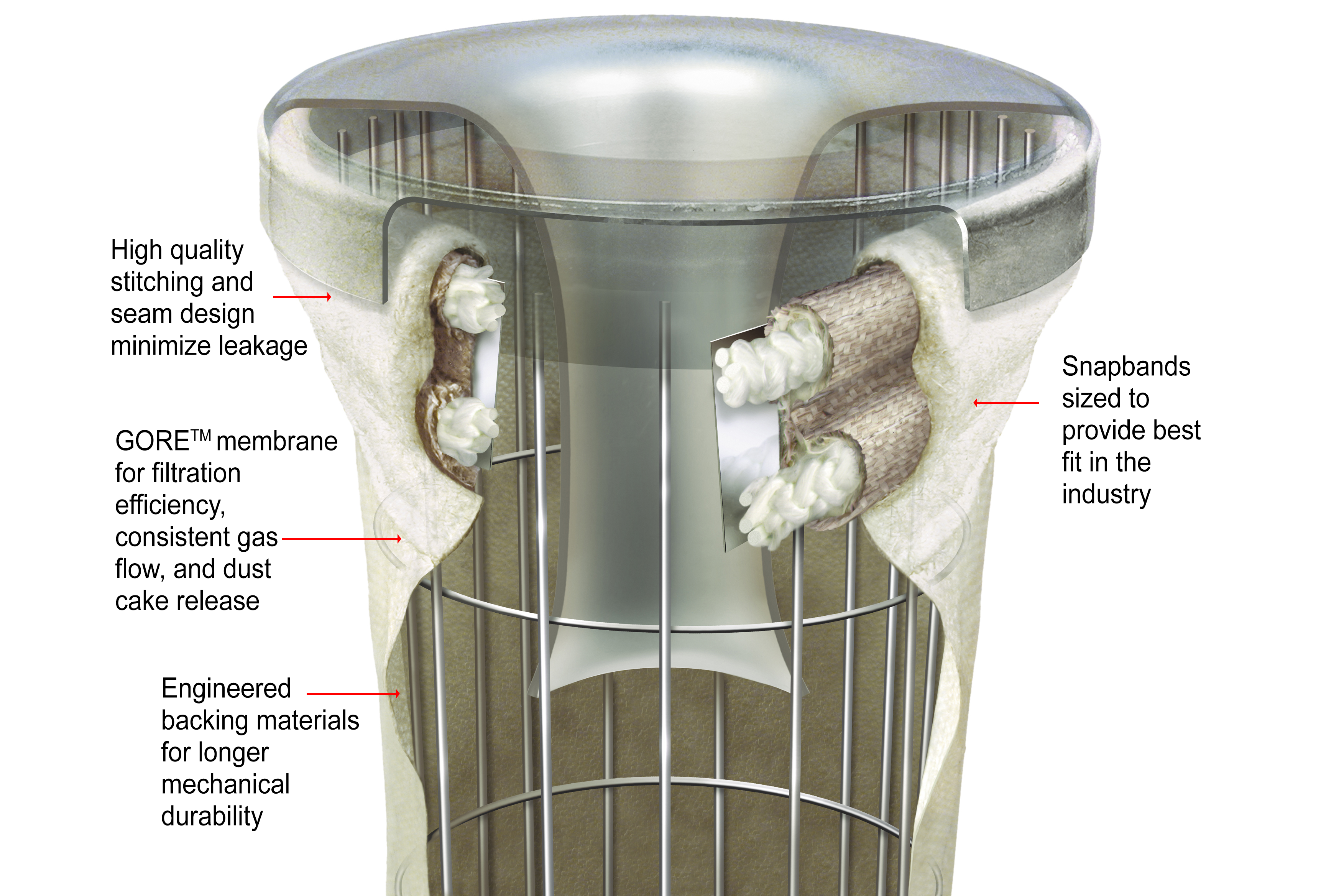

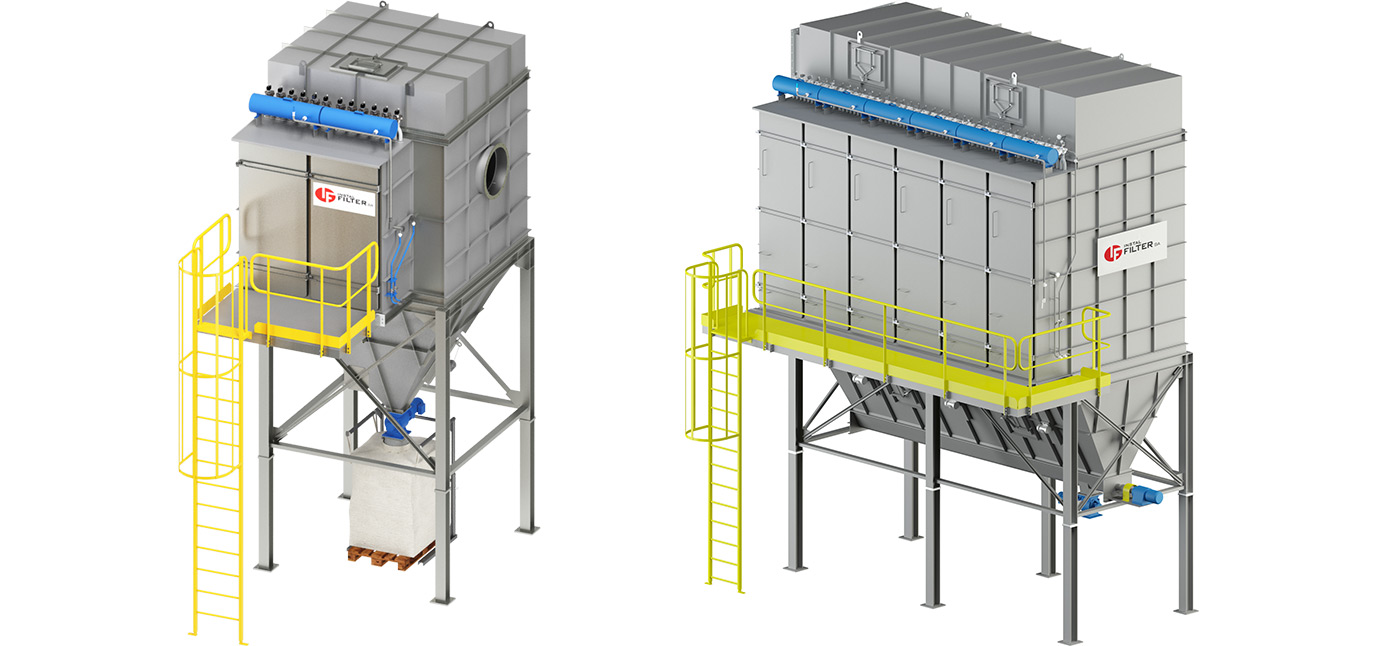

Woven fabric handles are also sewn. While the air-to-cloth ratio is of utmost importance for DPM-Model Bag Filters the can velocity has no impact on the design since the gas flow to bags is horizontal. Bag filters tend to have the lowest equipment investment costs and are generally tolerant of a wide range of process conditions making them a good choice for a wide range of applications. The Four Key Baghouse System Design Variables For a dust collection system to function ade- quately engineers must design and operate the system to maintain the 4 key design parameters of CFM FPM Vacuum Pressure and Air to Cloth Ratio or AC. Most baghouses use long cylindrical bags or tubes made of woven or felted fabric as a filter medium. Forcefully pushes air through bags. Kice CR Style Filter. An interesting approach in this group is the one proposed by Nguyen 9 in where a prototype filter is designed using constrained. A filter bag calculation can also be made because filter bags are round.

A wise filter selection can minimize process. Access is made on one side of the bags in order. An interesting approach in this group is the one proposed by Nguyen 9 in where a prototype filter is designed using constrained. Working of Bag Type Fabric Filters In pneumatic conveying systems handling fine or dusty material the method of filtration that has become almost universally adopted is a bag type fabric filter. The majority of dust collector filters are 5 inches up to 6 inches diameter round tubular cloth bags that are open at one end. While the air-to-cloth ratio is of utmost importance for DPM-Model Bag Filters the can velocity has no impact on the design since the gas flow to bags is horizontal. Bility is called bag reach and is the maximum number of rows from the nearest walkway.

Post a Comment for "Design Of Bag Filter"