Diesel Fuel Polishing System

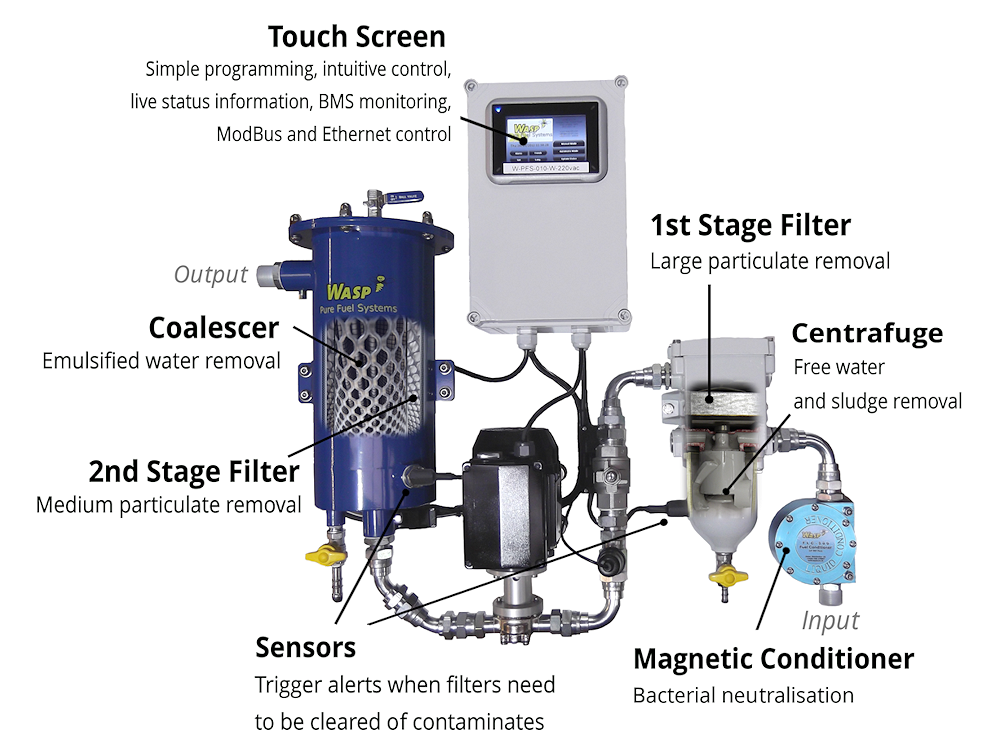

Diesel fuel polishing system. Fuel Polishing is the process of passing the fuel through a Fuel Conditioner see the FAQ Section below for how a Fuel Conditioner works that will break apart the agglomerated asphaltenes reducing the clumps to a size where they are returned into solution and the fuel again becomes clear and bright hence the term Fuel Polishing. TK Series Portable Hand-Held Fuel Polishing System. Personally I think that fuel polishing only makes sense where youve got a separate day tank feeding each engine and in which the fuel is being continuously circulated through a fuel polishing system in order to ensure that the fuel is as clean as it can be before it reaches the normal primary and secondary filters.

IPUs Diesel Defence fuel polishing systems work at the tank removing water microbial growth aka. 480 GPH to 1800 GPH. They can also be used for industrial Fuel Polishing applications inside a building.

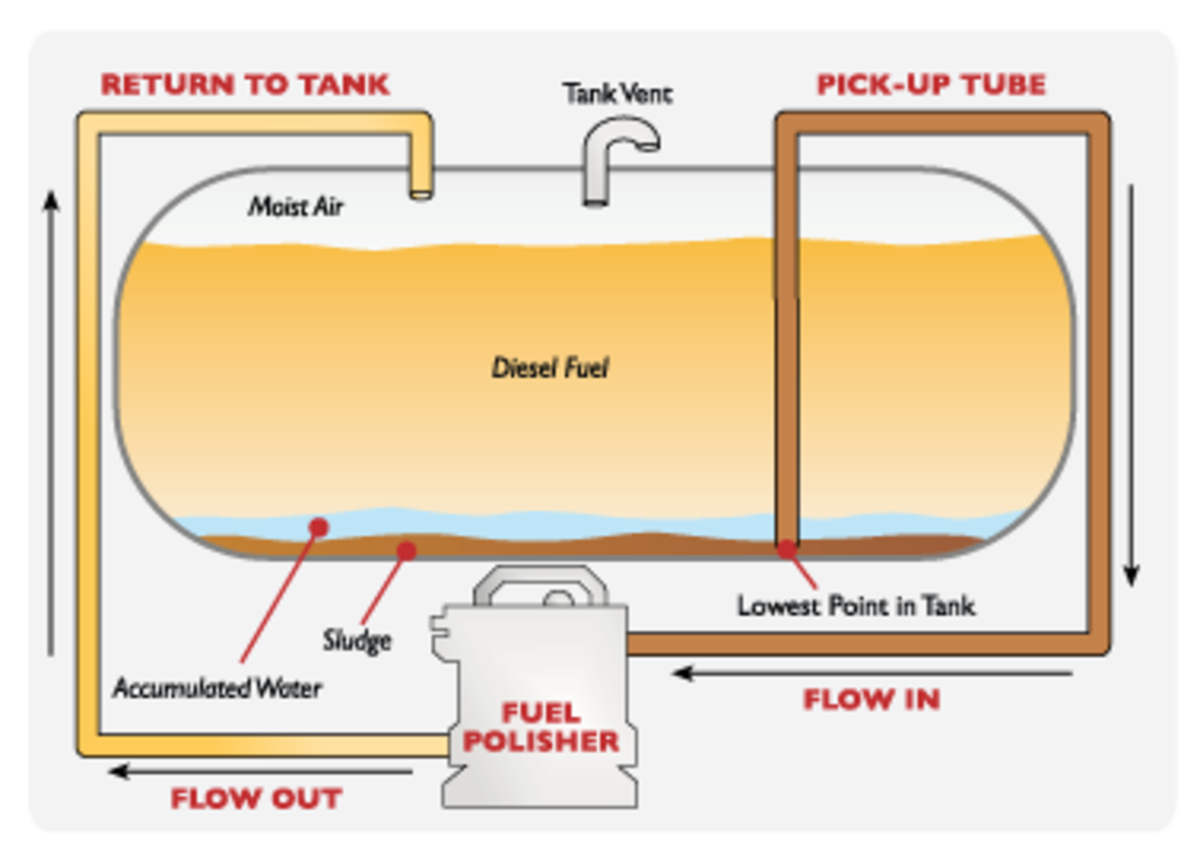

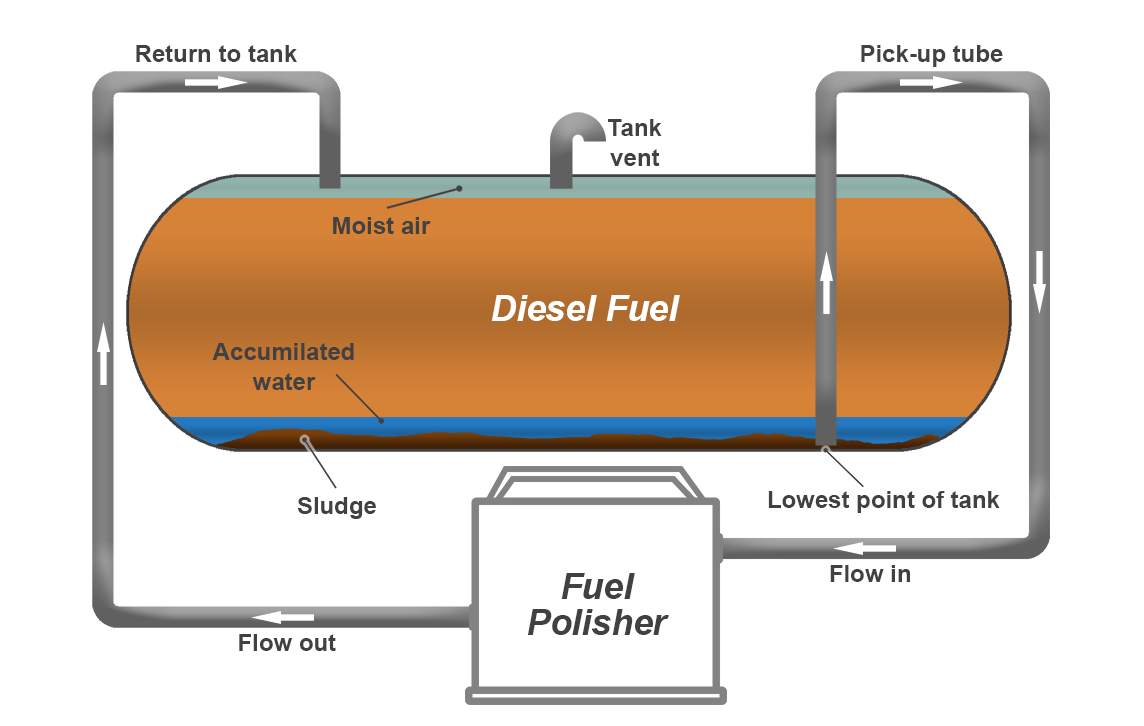

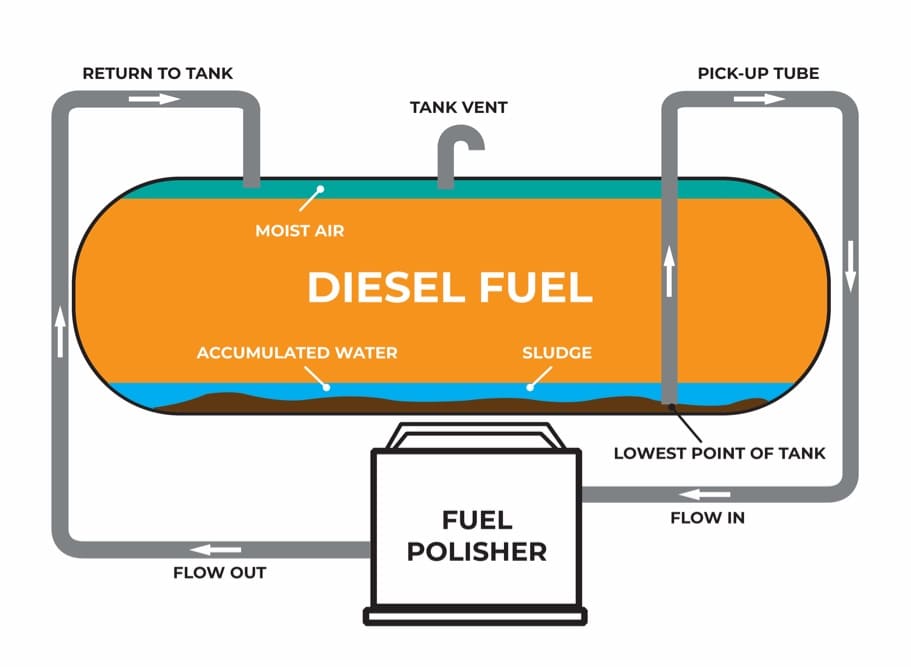

A fuel polishing system is usually connected directly to a diesel tank with two separate lines. What is diesel fuel polishing and what is not diesel fuel polishing. A Reverso Fuel Polishing System is the most efficient way to completely remove free water and particulates to help ensure diesel fuel quality for various tank sizes in marine and industrial applications with an installed or portable system.

Our diesel tank cleaners are the most effective method of cleaning your diesel fuel tank not only do they sanitise the tank but they will also keep them safe from future diesel bugs. The intake line diesel is drawn into the polisher with a pump is situated with its opening at the lowest possible point in the tank. Its just about impossible to prevent all water from.

Our systems filter out particles to below 1 micron can and commonly the water content in the filtered fuel is lower than fuel directly from refineries. Also for boats generators and trucks. And the polishing system pickup should be close to the bottom of the tank closer than the primary engine pick up ensuring that it removes all or as much water and debris as possible.

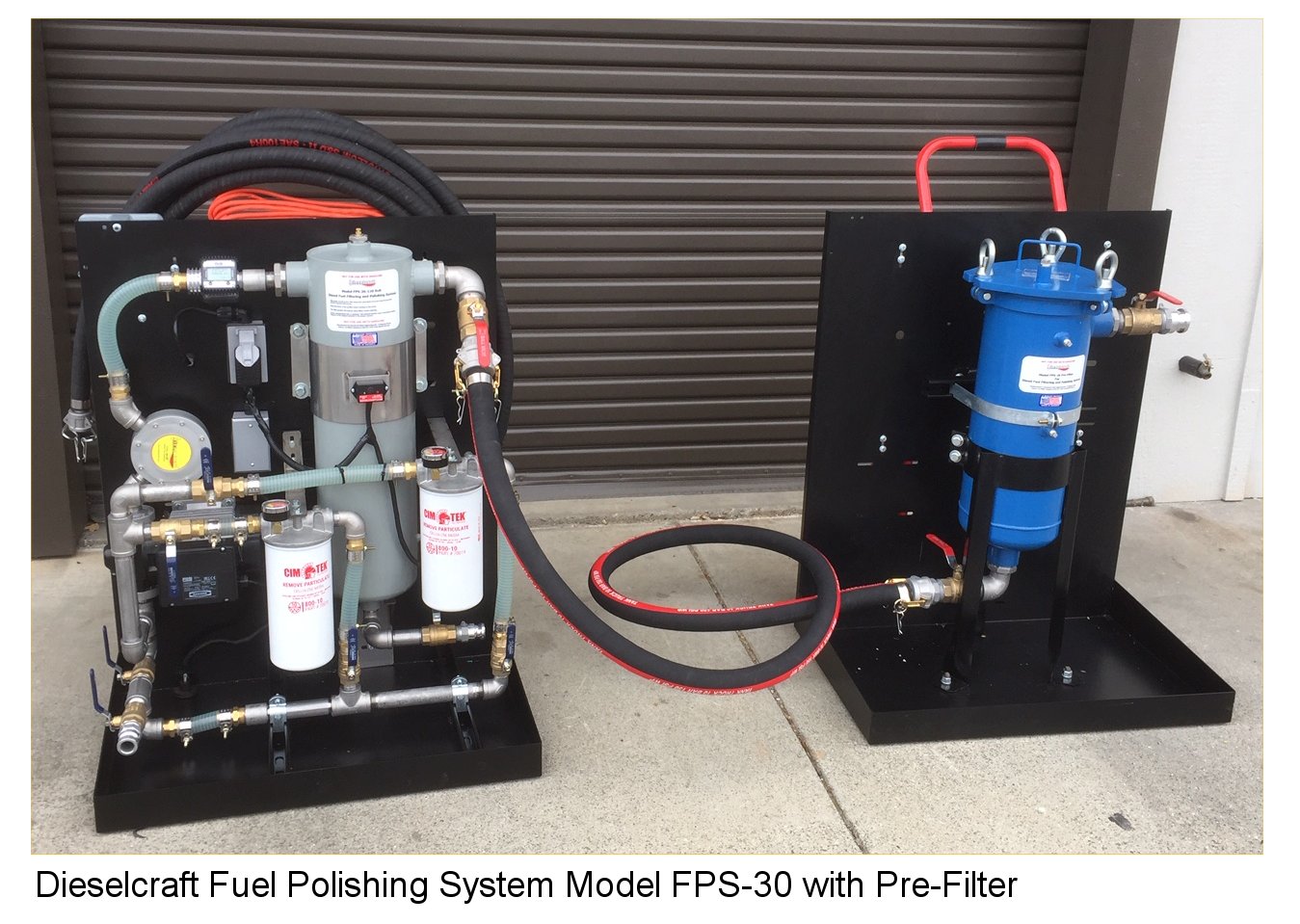

Water and particulates in diesel fuel can result in poor performance damaged components or unexpected engine failure. The FPS-CP-3 is a basic tank cleaning system designed for the transfer water removal polishing andor re-circulating of diesel fuel in storage tanks in ground as well as above ground. Some professional services also clean the tank while its empty.

Fuel polishing is pumping all the fuel out of your fuel tanks running it through a filter to remove water and debris and putting it back in the tank. A fuel polishing system pumps all the fuel out of your fuel tanks runs it through a filter to remove water and debris and returns it to the tank.

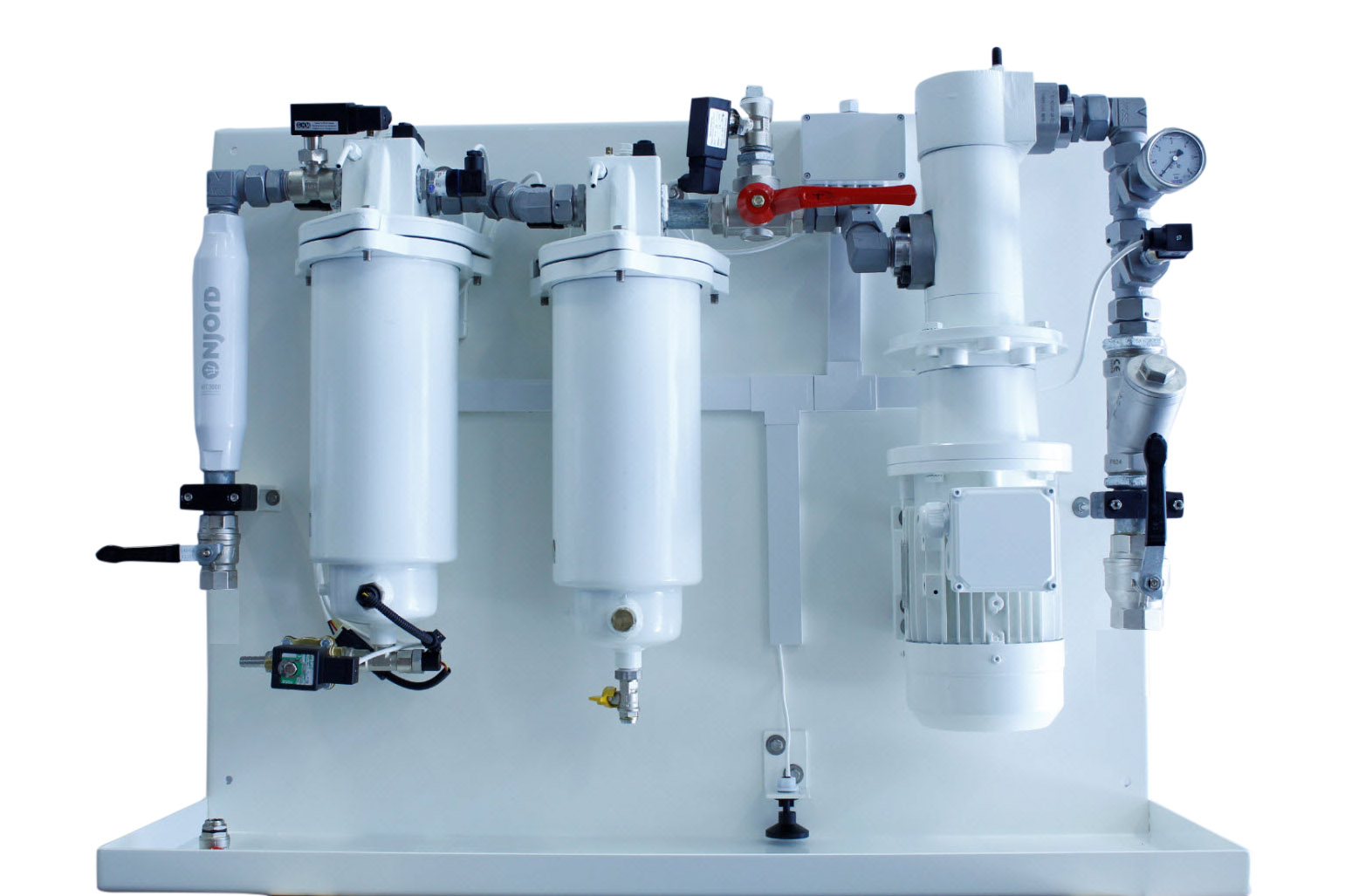

Njord Absolute Diesel Polishing Systems - APS Series.

Cleaning the stored diesel fuel you use for standby power. 480 GPH to 1800 GPH. Over time stored fuel for back up generators or on boats degrade and become infected with water from condensation. A Reverso Fuel Polishing System is the most efficient way to completely remove free water and particulates to help ensure diesel fuel quality for various tank sizes in marine and industrial applications with an installed or portable system. The fuel system remains online during filtration and the result is a clean tank with fuel that performs like new. The TK-240 XT is a 12 volt system that circulates diesel fuel at 240 gallons per hour. Our systems filter out particles to below 1 micron can and commonly the water content in the filtered fuel is lower than fuel directly from refineries. Also for boats generators and trucks. A fuel polishing system pumps all the fuel out of your fuel tanks runs it through a filter to remove water and debris and returns it to the tank.

480 GPH to 1800 GPH. Our diesel tank cleaners are the most effective method of cleaning your diesel fuel tank not only do they sanitise the tank but they will also keep them safe from future diesel bugs. A fuel polishing system pumps all the fuel out of your fuel tanks runs it through a filter to remove water and debris and returns it to the tank. The XT package includes 15 feet of suction and discharge hose a handy spill tray and one 8 oz. The intake line diesel is drawn into the polisher with a pump is situated with its opening at the lowest possible point in the tank. A fuel polishing system is usually connected directly to a diesel tank with two separate lines. Some professional services also clean the tank while its empty.

Post a Comment for "Diesel Fuel Polishing System"